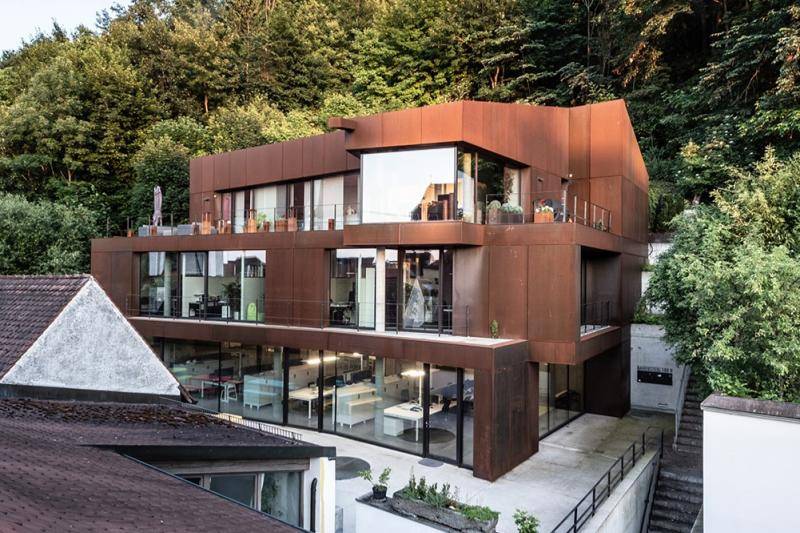

Extension of the restaurant "Steiereck"

In the extension of the Steirereck restaurant at Pogusch, concrete plays several roles – most importantly, it makes a key contribution to the overall energy efficiency of the building ensemble.

Spring 2022

Existing building: 756 m²

New construction: 2,957 m²

Steirereck Stadtpark GmbH

Structural engineering: Werkraum Ingenieure

Fire protection design: Kunz Die innovativen Brandschutzplaner

Infiltration concept and soil survey: Geologie Weixelberger

Vegetation concept for greenhouses: Green4Cities

Site supervision: Viereck Architekten

Building physics: rosenfelder & höfler consulting engineers

Lighting design: Ing. Johannes Jungel-Schmid

Building services engineering (HVAC): TBH Ingenieur

Landscape architecture: Client and Viereck Architekten

3D-printed washbasins: incremental3d GmbH

Concrete floors: PR Bodenschleiftechnik GmbH, BST-Bodenschleiftechnik

Concrete volume: Reinforced concrete excluding screed and concrete floors – 1,930 m³

Heating plant: 668 m³

At the heart of the Styrian Alps, the extension of the Steirereck restaurant at Pogusch unites traditional building culture with forward-looking sustainability. The challenge lay in blending the natural mountain setting with a contemporary hospitality concept to create a harmonious architectural ensemble.

As part of the Austrian research program “Stadt der Zukunft” the project was realized in collaboration with local craftsmen. It merges existing and new structures into an energy-efficient ensemble built to plus-energy standards. The design focuses on renewable energy, circular economy principles, and resource efficiency – from local food production and composting to the careful selection of ecological materials.

Concrete plays a central role: visible, functional, and thermally active. Through thermal component activation, ceilings, walls, and floors serve as heat storage elements. Water-bearing pipe systems absorb surplus energy from the greenhouses and release it during operating hours. An innovative system that significantly reduces heating demand.

The new buildings were constructed to low-energy standards with passive house components and feature controlled ventilation with heat recovery. Exposed concrete, polished floors, 3D-printed washbasins, and precisely crafted details underscore the project’s architectural and technical sophistication.

The result is an energy-autonomous flagship project that exemplifies sustainable architecture and forward-thinking building culture in an alpine setting.

© Text: Gisela Gary; Z+B Magazine; modified