Seniors residence Beeskow

In Beeskow, a senior citizens' residence and three urban villas have been built to provide a new home for up to 200 residents since 2021. The large-scale project called "BarbaraPark" relies on thermal component activation in all four buildings. The innovation of the project is that the filigree ceilings are already equipped with heating and cooling coils during pre-production in the concrete plant.

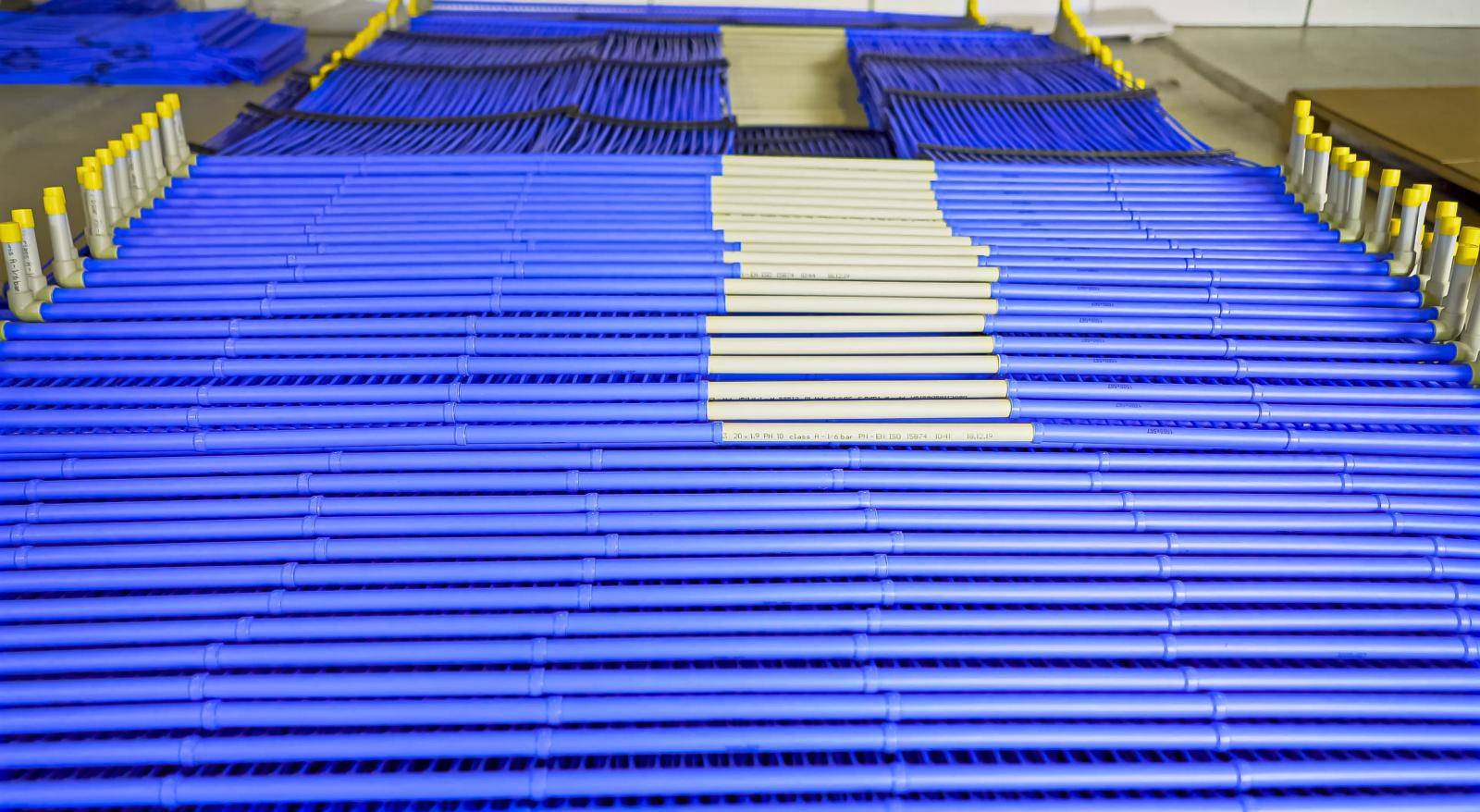

In Beeskow, a senior citizens' residence and three urban villas have been built to provide a new home for up to 200 residents since 2021. The large-scale project called "BarbaraPark" relies on thermal component activation in all four buildings. The innovation of the project is that the filigree ceilings are already equipped with heating and cooling coils during pre-production in the concrete plant.This process is highly automated. The so-called FILIblue modules, consisting of capillary tubes, are already planned and designed according to the room layout and respective ceiling sections and therefore only need to be placed on the steel tables in two simple steps. After concreting and the drying process in the concrete plant, the finished FILIblue air-conditioning ceilings are delivered to the construction site, thus completely eliminating the need to install capillary tube registers on site. This industrial pre-production simplifies overall coordination with other trades and also assembly in bad weather.

In Beeskow, the thermally activated filigree ceilings will be used for heating and cooling in the future. The energy supply concept is sustainable and efficient, because the required energy is obtained directly from the ground via an earth probe. In addition, the FILIblue system achieves a particularly high heating and cooling capacity because the capillary tubes of the individual modules are very close together with 20 millimeter center-to-center spacing. The arrangement of the modules in the concrete plant ensures that they are placed close to the surface, which means that thermal component activation takes place extremely quickly and ensures a comfortable climate throughout the building.

(Text source: Camila Vargas, GeoClimaDesign AG)